Base Sizing Guide

TUBING SIZE

TUBING SIZE

This doesn’t typically affect the legroom or the stability of the table, but it can affect the “rigidity” of table if the tubing size is grossly undersized for the intended application. It is also an important factor for both aesthetics and support for the tabletop. Too small of a material size will look dwarfed by the top, and may look awkward. Too large of a material size may look too bulky for the application and will increase the cost of the base unnecessarily. Different bases are made from different material shapes, such as square tubing, rectangular tubing, or flat bar. Below lists how we typically come up with a recommendation for tubing size for a given application:

1” square – Only recommended for small tables, such as end tables, or coffee tables with lightweight tops.

1-1/2” square or 1×2 rectangular tubing – Smaller, lightweight applications. Can be suitable for bench applications depending on the base design/style

2” square– minimum size recommended for dining applications. Suitable for most sizes and medium weight applications

1×3 Rectangular – Suitable for smaller dining applications. Material can flex under heavier or larger tables, so it is not recommended for larger dining tables, counter height, or bar height applications.

3” square or 2×3 rectangular – Recommended size for larger bases or for applications with heavier tops. Suitable for almost all size and weight applications.

4” square or 2×4 rectangular – Will provide a “massive” look to the base. Not recommended for smaller applications as the larger material will cause the base to lose its shape. This is the recommended material size for extremely large and/or heavy tabletops as it will look the most proportionate and best support the weight.

EXAMPLES

EXAMPLES

1/2″ thick glass top, 40″ W x 84″ L, dining height – The minimum base size we would recommend for this top would be 18″ W (from #1, stability) x 60″ L (12″ of overhang on both ends). This would allow for the most amount of leg and chair room while minimally meeting the other requirements. A base size of 26″ W x 66″ L would be a more conservative recommendation.

3CM thick stone top, 60″ W x 120″ L, dining height – The minimum base size in this instance would be set by step #2, regarding adequate support for the stone, in both the length and width, which would put the base size at 32″ W x 92″ L. However if a plywood underlayment was used, we could safely drop the base size down to 28″ W x 84″ L to allow for more chair room around the base.

1-1/2″ thick wood top, 36″ W x 72″ L, bar height – For the width, the minimum would be set by the stability requirements, which would be 26″ W. The length of the base could be as little as 42″. We would likely recommend 28″ W x 54″ L for this application to give some extra stability insurance.

1/2″ thick glass top, 60″ round, dining height – Considering adequate support for the top, the base width should be at least 36″ so as to not exceed 12″ of overhang

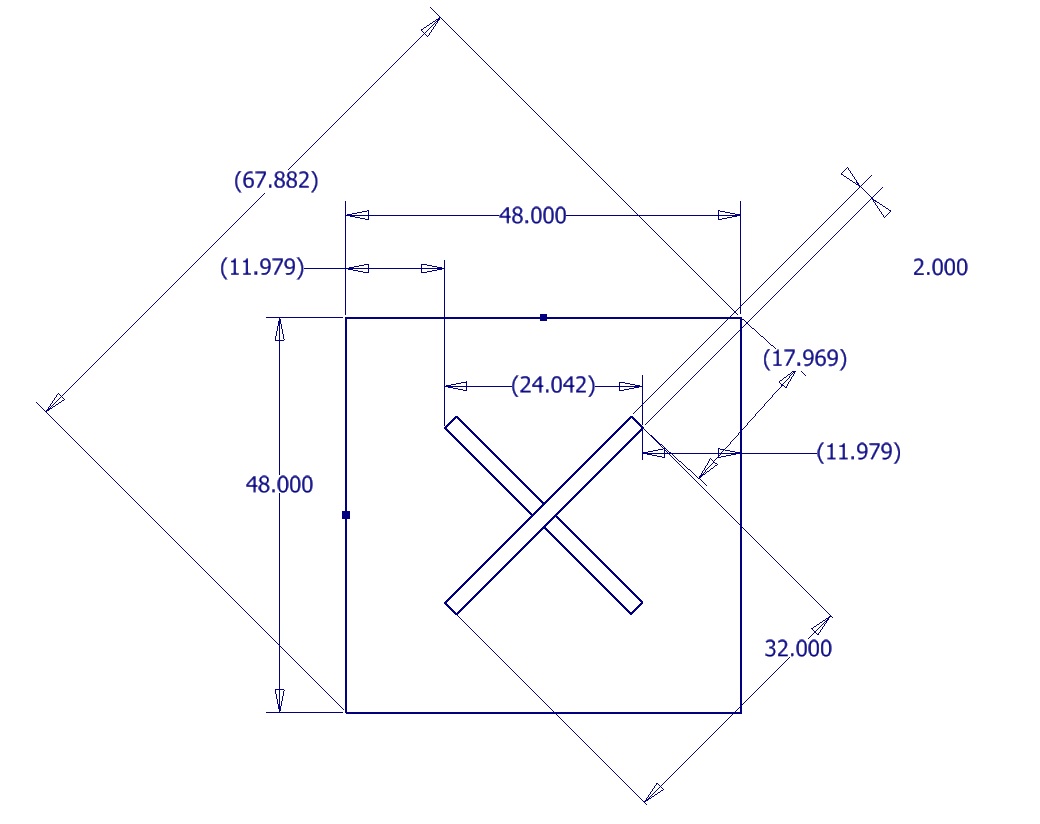

3CM stone top, 48″ square, counter height – Square tops are often confusing to measure properly, since the size of the square is measured from the width of the flats, however most of our bases are measured from “corner-to-corner”. To size the base according to the same measurement scale the top is measured from, we use the Pythagorean Theorem to determine the size square of the base, using A² + B² = C². At counter height, the base should be at least 22″ W. Giving a little extra security, we would recommend a 24″ base, so the base would need to have a 24″ box footprint. This works out to a base width of 32″ (see picture to the side for reference).

1-1/2″ thick wood top, 36″ W x 72″ L oval top – Oval tops can be one of the trickiest shapes to size properly. We recommend contacting us with your top dimensions and base preference so we can draw the base with the top to scale and determine the proper size.

3″ thick wood, 48″ W x 108″ L, dining height – With the massive wood top, adequate support to the top is most likely of no concern. The base could be as little as 18″ W x 68″ L and function perfectly. However we would typically recommend going a little wider to prevent someone leaning heavily on one side and possibly tipping the table over, so 24″ W x 72″ L would be our conservative recommendation to maximize leg and chair room.

STEP #1 – STABILITY

STEP #1 – STABILITY

TUBING SIZE

TUBING SIZE EXAMPLES

EXAMPLES