Metal Table Legs vs Metal Table Bases

Metal Table Legs or a Metal Table Base: Which is right for you?

The terms “Metal Table Legs” and “Metal Table Base” get tossed around a lot, sometimes interchangeably, but what really is the difference and is one better suited than the other?

Terminology and Definitions

“Metal Table Legs” and “Metal Table Base” can refer to the exact same thing. One refers to “legs” for a table and one refers to a “base” for a table, but the base can be legs and legs can be a base, so the terms can be used interchangeably. However, unofficial industry standards typically will refer to “metal table legs” as individual pieces that make up the support for a tabletop and a “metal table base” as a single piece base that the tabletop can rest on or is secured to. Hairpin legs, post legs, or H or X-Frame metal table legs would fall under the “Metal Table Legs” category, for example. Similarly, a parsons table base, spider base, or pedestal bases all would fall under the “Metal Table Base” category. For simplicity, we here at ECon Welding will typically refer to any product that is a free-standing design as a “base”, and any product that relies on the connection to the tabletop to maintain stability as “legs”.

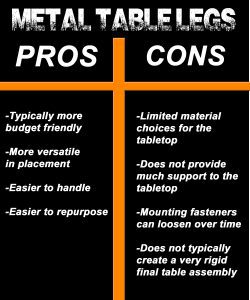

Metal Table Legs

As stated above, metal table legs rely on the connection to the tabletop for the assembly to work. For example, our H-Frame style metal table legs could not be used for a glass top application. Even if you could balance the legs to keep them standing up with the glass on top, as soon as the table is bumped into, the entire assembly would come crashing to the ground catastrophically. However since a connection to the tabletop is assumed, table legs can be made much smaller in profile since they don’t need to be free-standing. This usually allows for the legs to be able to be flat packed, and shipped via common courier, which equates to a more budget friendly product.

Generally speaking, table legs are usually sold in sets of 2 or 4 depending on the design. Hairpin legs and post legs are designed to put one leg towards each corner of the top, needing 4 per table. More contemporary designs of metal table legs such as the H-Frame or X-Frame style legs only need 2 per table, one towards each end.

Since multiple pieces are needed to fully support the tabletop, table legs are significantly more versatile than a table base, as the leg location can be fine-tuned during final assembly to fit in the exact location that works best for your application. They can also be removed and reused on various length (and sometimes various width) tabletops.

There are some significant disadvantages with using metal table legs instead of a metal table base. Since the stability of the table relies on the connection to the tabletop, the overall rigidity of the table is dependent on how secure the connection to the tabletop is. Soft wood or plywood surfaces that the legs are mounted to will almost always have a small amount of flex to them, which causes the whole table to sway back and forth with the flexing surface.

Installation of the legs to the top is also significantly more time consuming with table legs, as typically the legs need to be installed on the top upside down, then the entire table needs to be flipped over.

Lastly, with any kind of lateral force or racking on the table assembly, the forces go directly through the fasteners holding the legs to the tabletop. This may not be an issue, especially at first, but typical installations using only wood screws to secure the legs to the top will almost always gradually loosen over time, creating more and more sway in the table. The solution to this problem is to use threaded inserts in the wood top and bolts to create a stronger connection. However this adds an additional expense and significantly more time and potential for error during the table assembly.

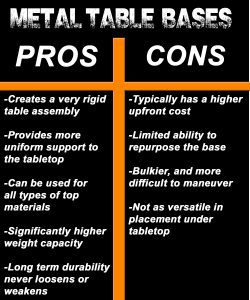

Metal Table Bases

Metal table bases as we manufacture them are typically single piece, fully welded bases that are completely free standing in design. The bases are made to work as-is, and do not rely on any other component of the final assembly to maintain their stability or rigidity. Table bases typically have an inverse list of pros and cons to metal table legs. The installation of a metal table base is about as simple as it gets: Simply set it in place, and place the top on the base. We don’t recommend relying on gravity alone to hold the top in place, so it’s still recommended to secure the top to the base either with a few screws or an adhesive. Glass top applications use a rubber bumper that goes in between the glass and the metal base to keep it from sliding around.

Our bases are fully welded, and do not rely on nuts and bolts to hold the base together, which creates a very rigid table that will never loosen or weaken over time with use. Since our bases are free standing, they are often used in applications where the tabletop requires additional support from the base.

Metal table legs typically only support the top where the legs are positioned, but a metal table base can have a full support frame, or contain significantly more contact points with the top, which can provide much more uniform support to the top. This can be especially useful for glass tops, thin stone tops, and thin or soft wood tops that may sag or break with a long unsupported span.

Unlike the advantages to table legs, table bases are usually large pieces that are costly to ship. They will have very little versatility to their application use since the base is manufactured to fit a specific size and type of top. They can also be difficult to maneuver to get in place, and we’ve had projects in the past where a customer ordered a base that was too large to fit through their doorway!

Should I Buy a Set of Metal Table Legs or a Metal Table Base?

There are some applications where one option is the obvious solution. Glass top applications or stone tops without a plywood underlayment are almost always recommended to be paired with a metal table base. Staging applications, products used strictly in photo shoots, projects on a tight budget, or any application requiring a total knock-down assembly should use metal table legs. But other than that, we tend to lean towards recommending metal tables bases for most applications. Most people who purchase custom made furniture do not plan on changing out the top only in the future, so the cons of a choosing a base over a set of legs are usually narrowed down to space constraints and upfront costs. The upfront cost difference of a metal table base over a set of metal table legs may seem substantial, but in the long run the long-term durability of a metal table base and the added support it gives your tabletop will likely more than make up for the difference in price. The extra cost is negligible considering the long-term application. Assuming the base can fit inside your doorway, we can almost guarantee you will be much more satisfied with a metal table base over a set of metal table legs.

If you like the idea of a base vs a set of legs, but are cautious about your ability to properly size the base for your table build, you can read through our Base Sizing Guide to be able to make a confident decision or Contact Us for our recommendation.